Turbostart air starters for gas turbine engines- gas turbine sử dụng cho khởi động động cơ

Đặt mua Turbostart air starters for gas turbine engines- gas turbine sử dụng cho khởi động động cơ

Turbostart air starters for gas turbine engines- gas turbine sử dụng cho khởi động động cơ

Bạn vui lòng nhập đúng số điện thoại để chúng tôi sẽ gọi xác nhận đơn hàng trước khi giao hàng. Xin cảm ơn!

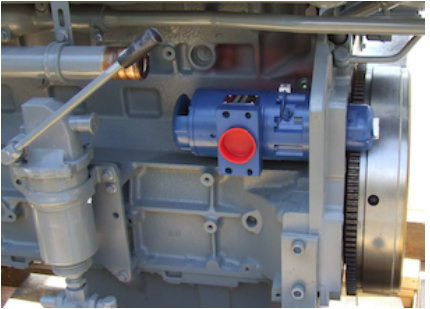

TurboStart 56 Series Gas Turbine Air Starter

TurboStart 56 Series Gas Turbine Air Starter

Đánh giá

Chưa có đánh giá nào.